Melton Fabric: History, Properties, Uses, Care, Where to Buy

Table of Contents

Introduction to Melton Fabric

Melton wool is a fabric composed of blends of the best wool fabrics. The fabric is woven in a twill pattern. Melton wool is often thick and firm, with a bit rough surface, and it is frequently used to create more strong, significant textiles such as coats and blankets, among other things.

Melton wool frays minimally or not at all due to its dense, quasi-felted structure, which is characteristic of the material. It provides exceptional warmth, has excellent moisture-wicking characteristics and is tough and durable, making it the most resistant of all woollen fabrics.

What is the History of Melton Fabric?

The origin of Melton wool production may be traced back hundreds of years in Wales, Scotland, and England. Melton wool was first manufactured in the Leicestershire town of Melton Mowbray, still produced today.

At that time, this modest town in the east midlands was the country’s hub for fox-hunting and other outdoor activities. Melton wool’s waterproof properties made it the optimal textile for making hunting coats, including the famous scarlet and black fox hunting jacket, which is still in production today.

Melton Mowbray and its nearby region developed into a centre for wool production, and the technique for Melton wool spread throughout the British Isles due to its success. The name Melton wool persisted, and that quiet local village is still remembered as the source of one of the best fabrics available today.

Properties of Melton Fabric

- It is a thick and dense fabric.

- It has a soft fabric. It can be easily cut using a pair of fabric scissors.

- It has a smooth and brushy surface.

- Has good heat retention abilities

- The fabric is pliable and can be used to drape

How is Melton Fabric Made?

Melton fabric is heavily ‘fulled,’ a wool-making process that removes oils, dirt, and other contaminants from the wool and thickens it. Fulling is accomplished through two procedures: scouring and milling.

Scouring is a procedure that removes all wool contaminants such as dirt from the fabric, whereas milling (also known as thickening) is a process that increases the thickness and handling of the woven or knitted wool by exposing it to friction, moisture and heat during the weaving or stitching process.

Fulling was historically done by hammering the woollen material with a club or even with the fuller’s hands or feet.

Where is Melton Fabric Made?

The fabric is made in England, Italy, Asian countries and China, the market leader in the textiles market. The raw materials are sometimes sent to China to make the finished product. There can be differences in the quality of the material depending on the country of origin.

Common uses of Melton Fabric

Melton fabric is commonly used for heavy outer garments and upholstery sometimes.

Daily wear

The fabric is used for heavy outer garments like coats, jackets, blankets and other garments which can be used to protect one from the cold and rainy weather. In light wearing garments, the fabric is used as a lining.

Home décor

The fabric can be used for bed sheets, cushion covers, mats and even car seats.

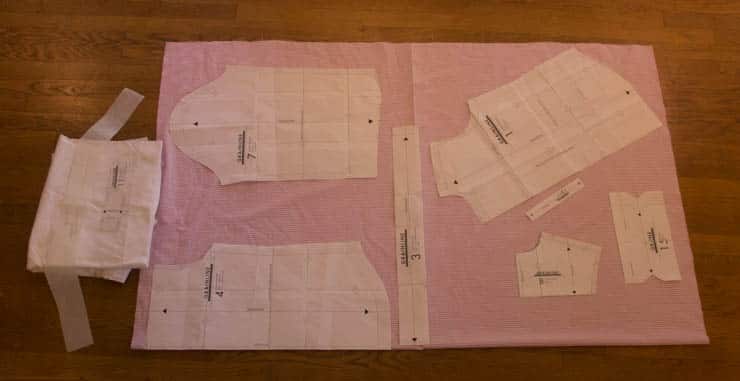

Sewing with Melton fabric

Melton fabric can be sewed easily using the right sewing essentials and sewing notions and supplies. Since the fabric has a dense and thick structure, it does not fray, allowing the material to be easily sewed.

However, any fabric containing wool thread will shrink significantly when subjected to steam and high temperatures. So same is the case for Melton; consequently, before sewing with Melton, steam the cloth thoroughly to avoid further shrinkage.

You can stitch the fabric using the best sewing machines like the Brother SE600. Since Melton is so dense, stitches sink into the cloth and become almost unnoticeable. As a result, a small amount of uneven topstitching will likely go undetected.

Even though the fabric is relatively easy to sew than other wool fabrics, one should still use the correct sewing threads and needles to create patterns and designs on the fabric of one’s choice.

Dyeing with Melton fabric

Even though it may be unheard of, Melton fabrics can be dyed. The process is useful for designers and consumers with unique styles and preferred designs.

The fabric can be dyed depending on its composition of the fabric. If made using rayon, acrylic, and other synthetic threads, the Rit All-Purpose Liquid Dye can be used as the best fabric dye available.

How to care for Melton Fabric?

Melton fabrics aren’t so hard to care for and can easily be washed and ironed without posing as a hindrance.

Washing

- Melton fabrics should never be machine washed

- You should dry clean or hand wash the fabric

- Use cold water with a gentle soap when washing by hand

- The fabric can be dried by air-drying it on a flat exterior

Ironing

- Using a shark steam iron, press the fabric on the wrong side

- Use a medium, cool setting and a press cloth

- The fabric responds well to steam and easily shapes.

Where to buy Melton Fabric?

Melton fabric can be acquired from fabric and garment retailers. Clients may also get Melton fabric from online retailers and websites such as Fabric.com and Amazon, which have the best Melton fabric available, such as the gorgeous Fabric Merchants Wool Melton Coating.

It can be sold in several ways depending on the seller;

- By yard

- By Inches

- Can be cut to order

Price

Wool Melton is one of the more expensive textiles available due to its rich wool composition. Depending on the weight of the fabric, you may anticipate paying between $15 and $40 per yard for it. You should be at ease knowing that you will be paying for a high-quality fabric.

Conclusion

For a long time, Melton fabric has been used for everything from garments and accessories to home decor. Despite decades of use, the fabric remains a popular choice.

Sources