How to Use Fusible Interfacing Like A Pro

Fusible interfacing is a term that is frequently used but rarely understood by those who are new to sewing. It’s no surprise that people are perplexed and uncertain when it comes to terms like fusible interfacing; yet, fusible interfacing is not that hard and can be easily understood!

Of course, when you begin your sewing journey, you may come across things that are unfamiliar to you at first; nevertheless, with practice, you will become familiar with them, and Fusible Interfacing is one of them. With a little research and a dash of drive, you’ll be using fusible interfacing in your next sewing project in no time!

I’ll try to dispel any illusions about fusible interfacing so that you can understand and use it. Because there isn’t a lot of information regarding fusible interfacing on the internet, it’s about time that the topic is adequately discussed!

You should be an expert in fusible interfacing by the end of this guide, and you’ll have no excuse not to utilize it in your next project!

Table of Contents

What Is Fusible Interfacing and How Does It Work?

As a simple explanation, fusible interfacing is a heat-adhesive substance that adds rigidity to a cloth. Non-fusible interfacing is identical to fusible interfacing, with the exception that it is sewn to the fabric rather than heated.

Materials can preserve their form and firmness with fusible interfacing, which prevents fraying and fragile fabrics and keeps your fabrics firm and in shape. This is why fusible interfacing is such a useful and useful ability to have.

Ordinary interfacing is commonly used to firm up the cuffs and collars of Oxford shirts, as well as in the fabrication and firming of buttonholes; interfacing is highly versatile, and it is also widely used to keep fabric elastic without becoming misshapen.

As you can undoubtedly understand, there are many various methods of interfacing, each with its own set of characteristics and applications, each catering to a distinct texture or fabric.

As previously said, fusible interfacing is a fabric interface created by applying a high level of heat and iron to the fabric.

Non-Fusible Interface:

As previously noted, this is when you stitch the fabric on instead of applying heat to it to create the interface.

Woven interface:

A woven wrap is used to create this type of interfacing. This can’t be stretched or extended, thus it’s treated like fabric; the optimum texture for this type is woven, as the name suggests.

Non-woven interface:

This is the polar opposite of the previously mentioned approach, and it is quite adaptable.

Knitted interface:

this is typically used for knitted textures, such as a wool jersey or a fleece.

Various weights!

Interfacing, like every other component of sewing, is divided into three weight categories: heavy, medium, and light. Depending on the weight of the fabric, the interfacing will determine how strong it will be once they’ve been sewn together.

What’s the Best Way to Get Started?

Now that you’ve learned everything there is to know about fusible interfacing, including the numerous types, weights, and other details, it’s time to get started!

The first thing you’ll want to do when getting started is put your fabric flat on the ironing board, right side up – then lay the fabric you’ll be using to make the interface on the spot where you want it attached.

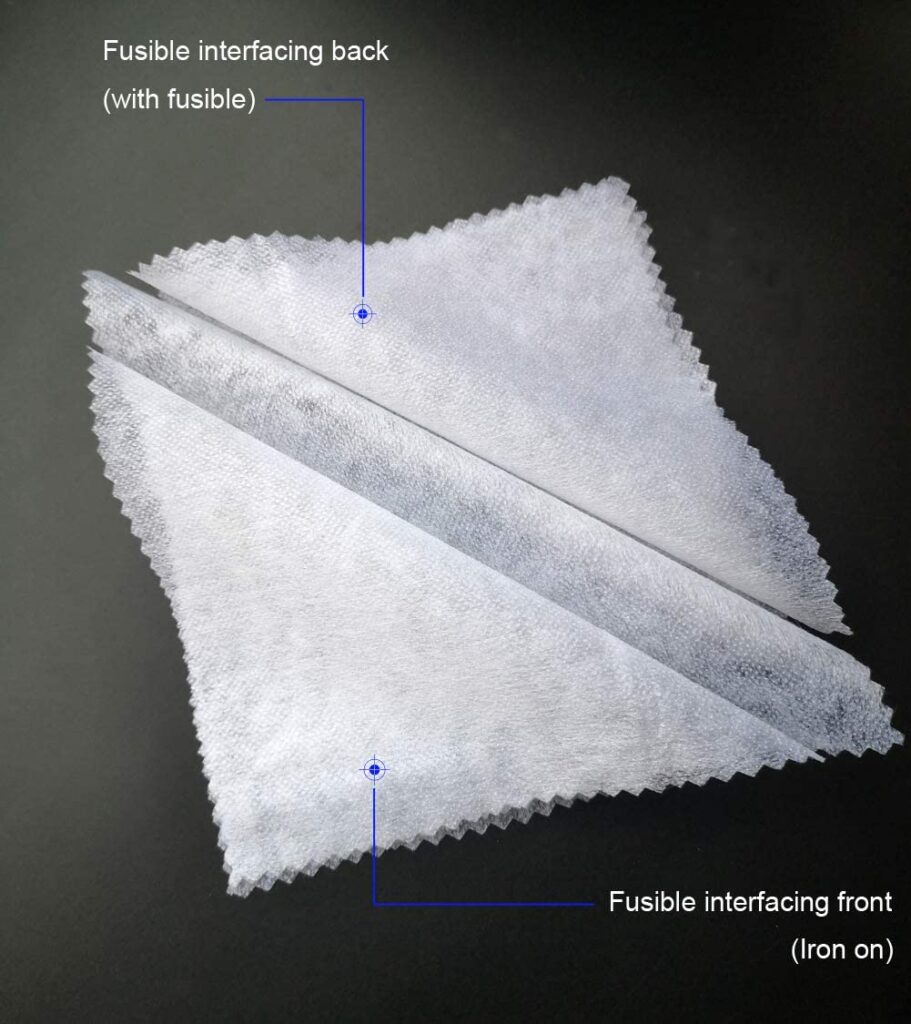

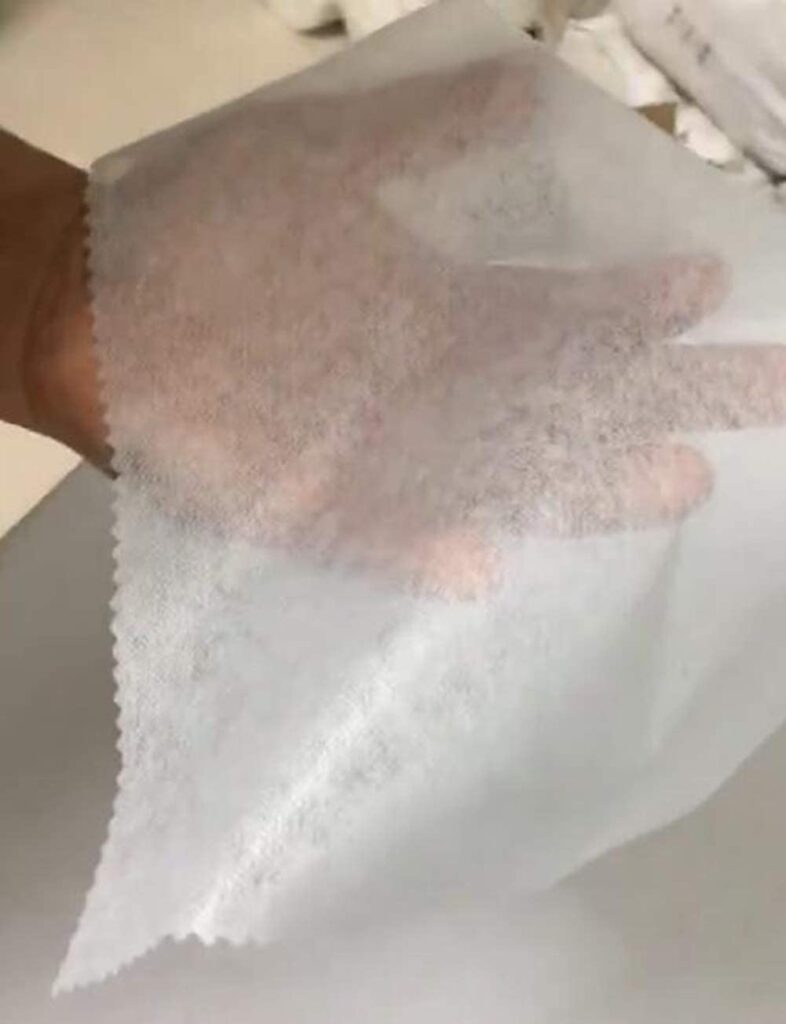

You must interface on the bumpy side of the fabric, and then apply heat and press the fabric for up to ten seconds to produce the interface. To make the interface, you’ll twist the iron, lift it up, and then place it back down. Then, as needed, repeat the process throughout the rest of your fabric!

You’ve just mastered the art of fusible interface!

It was not difficult, and just a tiny amount of reading was required for you to become completely knowledgeable in the subject; now you may teach others!

Although there are at least a hundred additional techniques used in sewing, fusible interfacing is the most adaptable. This is only the first step in achieving your sewing goals, and you’ll have the rest memorized in no time.

Sewing is not difficult if you put in the effort and regard it as an art form. You can use interfacing to make a wide range of clothes and fabric products, from wallets to sweaters, hoodies to shirts. Your collars and sleeves will be able to be firmer.

Fusible interfacing will maintain the quality of your garments for as long as you intend to use them or until they are worn out. Fusible interfacing is a great approach that, as you’ve surely heard, involves very little effort and can be done by anybody, at any time, with the correct tools.

Interfacing has a number of advantages, including fabric firming, as mentioned above for shirts and collars; it can strengthen and make a fabric less flimsy in areas where it would otherwise tear; and it can keep your fabric firm and nicely worn, so it does not wear away or stretch out of shape after the first time you put it on.

You’ll have a lot of options with all of the weights stated in this guide. The various weights are also available in a variety of colors, though when interfacing, the color white is commonly used. Don’t be afraid to try something new every now and again.

Get started on your next project right away!